Products

Logistic Systems

System pallets Transport

set of elements dedicated to handling, accumulation and / or distribution of goods to the specific positions that requires logistical operation . These transport systems seeking the ideal combination of efficiency and effectiveness of the procedures , shipping and handling of cargo units.

Advantages:

- Wide range of elements linked to the transport of cargo units

- Maximum economy and profitability in the transport of products

- Reduction in delivery times and installation costs

-

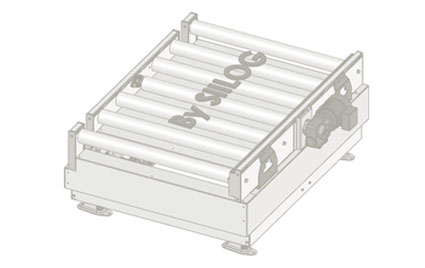

Roller Conveyors Systems

Motorized roller conveyors ( Ref.TR01 ) are used to carry Euro pallets, steel pallets and similar goods transport unit weights of up to 1,500 kg.

The customer’s request with detailed study can be produced with different characteristics.

The sturdy construction and modern and modular composition design in compliance with the European regulations for industrial machinery.

The guide system is carried out by a system of steel coated plastic to avoid damaging the pallet.Characteristics:

- Transport system high profitability and Economic long distances

- Easy corrective and preventive maintenance

- Constitution equipment for high durability in time

- Easy mounting accessories

Technical data

- Speed min. 0,20 m/s

- Max . 0.45 m/s

- Nominal width : min. 850 mm max . 1250 mm

- carrier level Top: min. 200 mm

- Weight : max. 1500 kg

-

Chain Conveyors Systems

The chain conveyor ( Ref.TC01 ) is ideal smooth grid pallet boxes and similar products, both lengthwise and crosswise .

Designed for high loads up to 2000 kg , the robust carrier capable of stabilizing high rates on shipping.Characteristics:

- Pallet quality is preserved

- Reduces costs with respect to spare parts and maintenance effort

- High operational safety

- Flexible mounting accessories ( sensor brackets , lateral guides , step plates , drives, supports

- Travel speed: 0.2 to 0.45 m/s

- Track width Transport length : 725 mm

- Cross transport width of track with any solution

- Payload unit : max. 6000 kg

- Carrier length : max. 8m

- carrier level Top: min. 450 mm

- Payload per pallet : max. 2000 kg

-

Turntable Systems

Turntable ( Ref.MR01 ) are used to change direction or turning goods on the conveyor.

The modular construction enables an optimal adjustment to differences applications in layout.

Can be equipped with the system or Ref.TR01 system Ref . TC01 , this system allows a range of from 2 to 8 staging points for maximum versatility. This system can reach speeds up to 0.75 m / s and 90-degree turning time is 6 seconds.Characteristics

- Fast , precise rotation of pallets , high performance

- Versatility for all applications in layout

- Modern design

- Safe transport without gaps

- Reduces the turning time

- Easy preventive maintenance and corrective

- Speed: 0.15 m min / sec / max . 0.75 m / s

- Weight : max. 2200 kg

-

Transfer Table Systems

Transfer Table ( Ref.MT01 ) is designed to power Ref.TC01 and Ref.TR01 carriers.

This technology transport stream or roller is also used for the grid boxes.

Possible inclusion of specially mounted guides getting high results in the direction of transport.

We fit in various scenarios using this product , being used to transfer pallets and hand them to storage systems and automatic recovery.Characteristics

- Capacity high throughput

- Easy corrective and preventive maintenance

- Smoothed transfer transportation

- Low number of units

- high yield, low cost

- Speed min. 0.2; max . 0.55 m / s

- Rise time : 1.5 seconds

- Overall height : min. 320 mm

- Pallet weight : max. 2200 kg ( 2755 pounds )

-

Roller Conveyors for Accumulation

Roller Conveyors for Accumulation ( Ref . TRA01 ) in mechanical and pneumatic versions are used for accumulation zones Call 0 pallets, grid boxes and other load handling items .

Through its specific use , increasing the rate of capacity and increasing the benefits of effectiveness and efficiency in transport.Characteristics

- system , minimal maintenance , and robust

- cost-effective system

- Soft transport pallets

- long useful life

- Easy mounting complementary accessories

- mechanical or pneumatic accumulation system

- carrier length up to 22 m

- Speed: 0:20 m / s

- Nominal width : 850

- 1050, 1250 mm

- Roll field : 175, 200 mm

- roll diameter in accordance with load carrying

- Pallet weight : 1500 kg

-

Roller Table Transfer

Roller Table Transfer ( Ref.MTR01 ) is used to transfer the pallets and pallets grid box into or out from high performance chain conveyors . This equipment has cadencia ability to transfer up to 500 pallets per hour . Especially installed at a location stops to secure and enable accurate positioning and alignment during the transfer.

Characteristics

- Treatment of sensitive charge carriers

- Increased availability for transporting pallets and pallets grid box

- High transfer performance robust equipment and long product life maximum throughput , reduced costs

- Maximum availability , high loads

- Transportation speed: 0.2 to 0.45 m / s

- Roll field : < 220 mm ( Euro pallets) / < 165 mm ( grid pallet box )

- Nominal width : 850 , 1050 and 1250 mm

- Payload per pallet : max. 2000 kg

-

Belt Elevator

The Belt Elevator is driven by a suitable vertical conveyor device for the most demanding requirements for speed, lift height and payload .

This transport system is extremely quiet and ready to be used for any number of stop positions.Characteristics

- CAPACITY Elevation calm;

- Versatility to fit any system scenario

- design flexibility of the system

- Low power unit – low power consumption

- easily adjusts to a variety of loads

- Acceleration: max . 0.5 m / s2

- Lifting speed : max. 2 m / s

- Elevator : max. 15m

- Pallet weight : max. 2 x 1500 x 1 kg or 3000 kg/li>

-

Conveyors Systems for Boxes

The distances within a facility are made with transport elements which are usually associated with high requirements for functionality and frequency of each and every one of the components forming part of the system.

Upon actuation motorization systems and presence control by mechanical or optical detection elements , it is possible to move in a controlled manner boxes or trays to desired positions .

SIILOG offers a continuous and adaptable transportation system according future prospects for growth and expansion by its customers.Advantages

- Robust system designed to withstand daily high-performance operation

- The project is ergonomic and compact which facilitates the operation tasks

- Low maintenance and easy execution of tasks

- Low operating costs

- High effectiveness and efficiency in the management of all processes

Automation / Software

-

Automation / Software

SIILOG puts at your disposal its warehouse management software aimed at small, medium, large companies for different business sectors.

Its main objective is to control, coordinate and manage all the processes that take place in a warehouse.

The different levels of functionality SIILOG Software let you tailor to your specific needs of each installation depending on the degree of complexity and automation of warehouse easily managing to adapt to optimize the growth of a business or new processes and volumes.

The software has been created and developed under the SIILOG brand and offers a support service and remote maintenance available 24 hours a day, 365 days a year.Advantages:

- Increased logistic productivity and reducing the number of operations.

- Total control of locations.

- real-time control applications.

- Productivity control of the workers.

- Elimination of errors in shipments.

- Increased speed in the preparation and submission of applications.

- Improving compliance with the deadlines of applications.

- Time reduction in countless jobs in the supply chain.

- Better use of physical and human resources.

- Drastic reduction in costs caused by the expiration dates or the unknown loss.

Logistic Modules

-

(PT) Plataformas e Passadiços

(PT)

As plataformas permitem aproveitar ao máximo a altura útil de um local duplicando ou triplicando a sua superfície e acondicionando-a como zona de armazenagem, vestiários, escritórios, etc. A instalação de uma plataforma significa a melhor solução para tirar partido do espaço disponível. É possível ocupar toda a superfície ou apenas as zonas mais altas do local.

São sistemas totalmente modulares desmontáveis e reutilizáveis, sendo muito simples modificar a sua estrutura, dimensões ou localização.Advantages

- Multiplicam a superfície de naves e locais.

- Adaptáveis às necessidades concretas de cada cliente, graças à grande variedade de medidas, tipos de pisos, sistemas de construção, etc.

- Montagem rápida e simples.

- Complementam-se com outros sistemas de estantes existentes.

Special Machines

-

(PT) Máquinas e/ou Projectos Especiais

(PT)

SIILOG estuda, projecta, desenvolve e instala qualquer sistema de armazenamento à medida, em função das características ou problemática especial de cada armazém.

Desenvolvemos ainda todo o tipo de máquinas que ofereçam rentabilidade aos nossos clientes ajustando o nosso projecto às necessidades concretas entre a SIILOG e o cliente.Advantages

- Assessoria, estudo, desenvolvimento e realização de projectos específicos.

- Ampla experiência na realização das mais variadas adaptações a necessidades específicas de armazenagem, linhas de montagem, criação de máquinas especiais;

- Respostas rápidas, eficazes e com garantia.

(PT) Sistemas Armazenagem Automática

-

(PT) Sistemas Armazenagem Automática

(PT)

SIILOG criou para a armazenagem automática de paletes um sistema que oferece alta performance de operação.

Este sistema de transelevador pode ser usado para caixas ou paletes, desloca-se ao longo dos corredores e realizam as funções de entrada, colocação e saída das mercadorias.

Os transelevadores são guiados por um software de gestão que coordena todos os movimentos operativos.

A gama de transelevadores adapta-se facilmente às necessidades de cada armazém quanto à capacidade de carga, dimensões, altura de construção e tempos de ciclo, pelo que se cobre um vasto leque de aplicações.Advantages

- Automatização das operações de entrada e saída dos produtos.

- Permitem a gestão de inventários controlados e actualizados em qualquer altura.

- Eliminam os erros derivados da gestão manual.

- Possibilidade de adequar-se a condições de trabalho especiais, como temperatura de congelação (-30º C), humidade extrema ou prestações especiais, como a de aumentar as velocidades de trabalho standard.

Logistics Modules

-

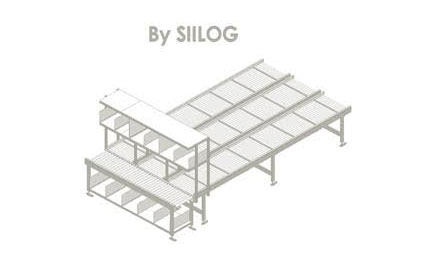

Conveyors Roller

treated steel and painted 316 Stainless Steel anodized Aluminium transportares linear , horizontal or inclined curved tapered roller Special accumulation systems PVC galvanized steel stainless steel. The advantage of this product, have high efficiency and are ideal for short distances and light loads . Because of being completely modular adapt easily to any layout.

-

Motorized Roller Conveyors

- treated steel and painted

- 316 stainless steel

- anodized Aluminium

- transportares linear, horizontal or inclined

- Curves tapered roller

- Special accumulation systems

- Transfer tables

- Tangential screen roll

- Tangential cord to roll

- Plastic toothed belt transmission

- drive chain

These devices were developed taking into account the reliability and reduced maintenance.

They have high efficiency and are the ideal solution for the transport of light and heavy loads. Because of being completely modular adapt easily to any layout. With this type of solution can be transported from the carton to a container of large size and high charge.

Designed in order to meet all the standards required by the European Community. They are so identified with the CE mark and are accompanied by the certificate and instruction manual. The rollers fitted these devices can be in: PVC, Zinc plated steel or stainless steel.

With the above models it is possible to implement the most varied layouts. thus solving the transport of products in a production unit. -

Belt Conveyors

Treated steel and painted 316 stainless steel anodized Aluminium transportares linear , horizontal or inclined Curves tapered roller Special accumulation systems Transfer tables Tangential screen roll Tangential cord to roll Plastic toothed belt transmission drive chain Depending on the belt speed and load , the drive rollers to the different configurations linger in order to efficiently transfer the drive torque to the belt . Designed in order to meet all the standards required by the European Community . They are so identified with the CE mark and are accompanied by the certificate and instruction manual.

-

Metallic Belt Conveyors

- treated steel and painted 316 stainless steel anodized

- Aluminium transportares linear , horizontal or inclined

- Curves tapered roller Special accumulation systems

- Transfer tables Tangential screen roll Plastic toothed belt transmission drive chain

This type of product is optimal for the transport of one or more materials easy to integrate in a layout robust in any type of construction is steel, stainless steel, aluminum .

-

Table Transfer

- treated steel and painted

- 316 stainless steel anodized

- Aluminium transportares linear, horizontal or inclined

- Curves tapered roller Special accumulation systems

- Transfer tables Tangential screen roll

- Plastic toothed belt transmission drive chain

Such equipment is ideal for in conjunction with conveyors, transfer tables serve to separate, store, collect or sort products or smaller subsets.

The various options available with the transfer tables find applications in many branches of industry. transfer tables are ideal for applications that require packaging and filling, also for the companies involved as electronics or production of small parts. This product has been designed and developed to comply with all the standards required by the European Community. They are so identified with the CE mark and are accompanied by the certificate and instruction manual. -

Work Station

- treated steel and painted

- 316 stainless steel

- anodized Aluminium

We developed this product as a complement to our layouts.

Product easy integration into any manufacturing and / or operating and quite ergonomic environment.

These tables can be combined without problems with other extensions , such as protection or energy. Because of the modular structure , the integration of different production and handling systems are possible.

Designed in order to meet all the standards required by the European Community .

They are so identified with the CE mark and are accompanied by the certificate and instruction manual.

PT

PT ES

ES FR

FR